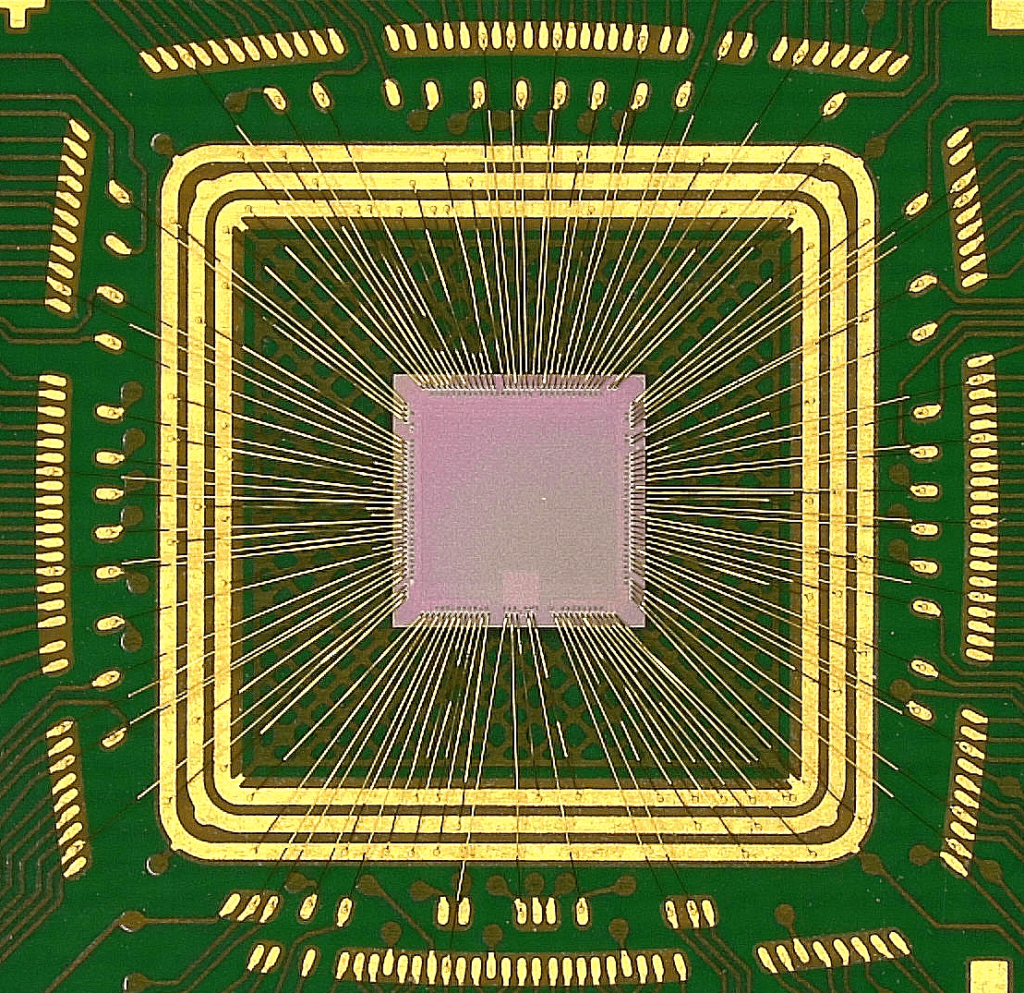

Chip on board / Chip on flex

Chip-on-flex (COF) semiconductor assembly processes eliminate many of the traditional assembly steps involved in IC packaging. In COF, a microchip or die is directly mounted on and electrically connected to a circuit built on a flexible substrate. The shorter interconnection paths yield improved performance, and the resulting final product is smaller, lighter, and simpler to design and manufacture, as well as less costly. Some of the key applications driving growth in the COF market include sensors, lighting, biomedical implants, and RFID devices.

QP Technologies (formerly Quik-Pak) has the capability to attach and bond die on printed circuit boards and flex circuits measuring up to 5″ by 8″ and even larger, using our extensive range of wire bond equipment. Using surface mount technology or adhesives, passives, transistors, diodes, connectors, and integrated circuit components can be mounted prior to chip placement for one-stop-shop assembly. The IC die on PCB or Flex Circuits can be protected with overmold, glob top encapsulation, frame and lid or custom covers. QP Technologies’ in-house design and fabrication options can expedite the custom tooling process by designing unique fixtures for your populated boards to aide in the manufacturing process and cutting valuable lead time.