Since establishing our substrate design and development service in 2020, demand for QP Technologies’ capabilities in this area has risen steadily, as customers seek to fill technology gaps that standard, off-the-shelf packages cannot accommodate. Custom substrates are a vital aspect of this service.

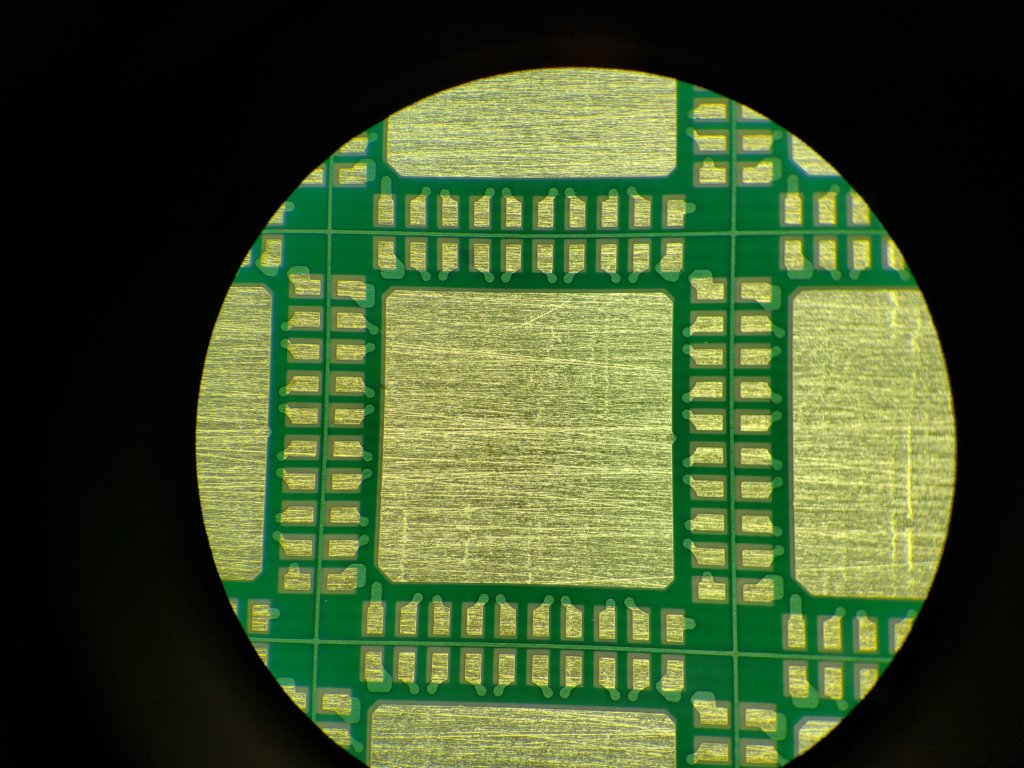

Using an interposer, the substrate provides mechanical strength and electrical connectivity to the IC package, facilitating build-up and integration of complex circuits. The material used to create the substrate depends on the desired properties of the device being manufactured.

As a chipmaker, you need a board package and assembly approach that can make the most of your unique design. Using advanced laminates such as FR-5, BT and ABF offers performance advantages, but these materials pose unique challenges. QP Technologies’ team leverages our proven substrate expertise to collaborate with you, ensuring optimal design, development and implementation of your customized solution.

To learn more about our custom substrate capabilities, click here to download our latest white paper.

To engage with us on design and development of a custom substrate for your product, click here.