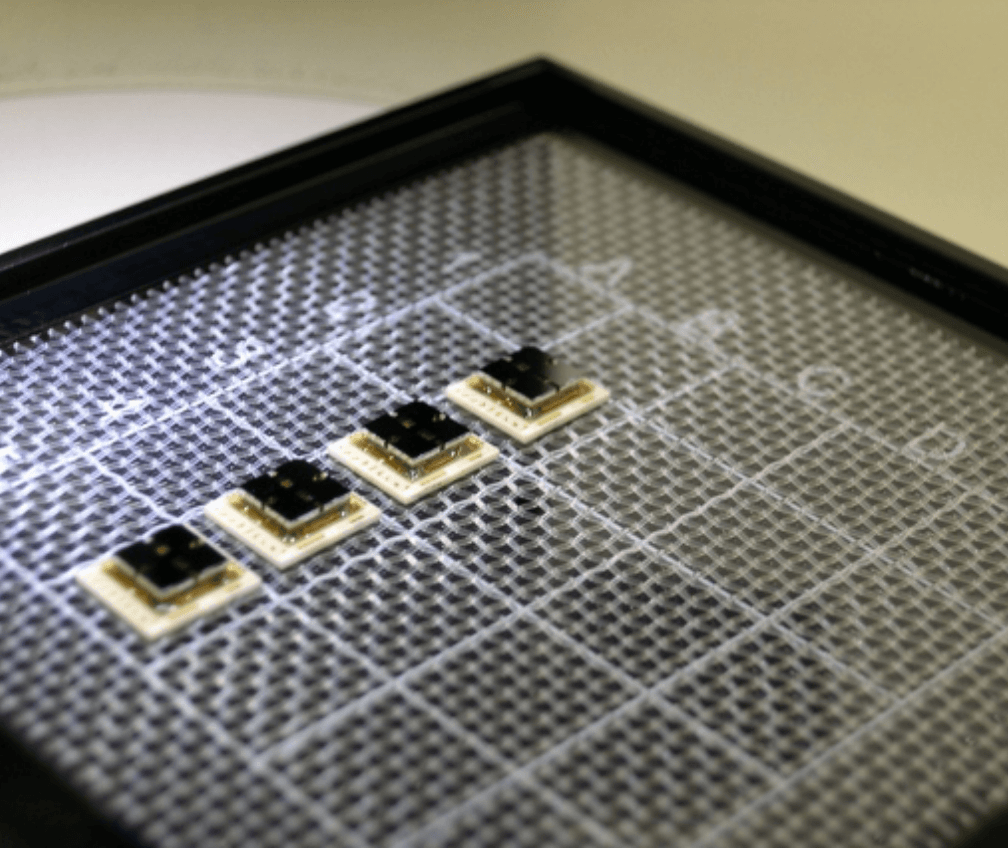

Flip Chip Bonding

Flip Chip assembly is the direct electrical connection of face-down (flipped) electronic die onto organic or ceramic circuit boards by means of conductive bumps on the chip bond pads. This process is quickly gaining popularity over traditional face-up wire bonding due to its advantages in circuit board real-estate reductions, performance, reliability, and cost over other packaging methods.

QP Technologies enhances bonding capabilities

QP Technologies (formerly Quik-Pak) has enhanced its Flip Chip bonding capability by installing a Finetech Pico Flip Chip bonder. The bonder is capable of placing pre-bumped devices within a 1µm placement accuracy. Assembly applications include µBGA, standard flip-chip, 3D packaging, optoelectronic bonding and assembly, sensors, chip on glass, and more.

QP Technologies Offers:

DEVICE BALL BUMPING:

- Solder ball bump to 305µm (0.012″) diameter on a 508µm (0.020″) pitch

- 96°C, 183°C, and 217°C alloys available

DEVICE/PARTIAL WAFER STUD BUMPING:

- Gold (Au) stud bumping of partial wafers and large die

- Stud bumping pitch down to 150µm

BONDING:

- Align down to 1µm placement accuracy

- Placement and bonding down to 100µm pitch devices

- Thermo-compression bonding of small gold-to-gold leads (highest accuracy)

- Thermosonic bonding of gold-to-gold leads (lower temperature)

- Hot air solder reflow for Sn, SnPb, and other solders

UNDERFILLS:

- Standard underfills for BGA and flip chip assemblies

- Reworkable underfills for BGA and flip chip assemblies where recovery of the substrate may be required