Additional Wafer Preparation Services

In addition to wafer backgrinding and dicing, QP Technologies (formerly Quik-Pak) offers a range of other services to further process your valuable dice.

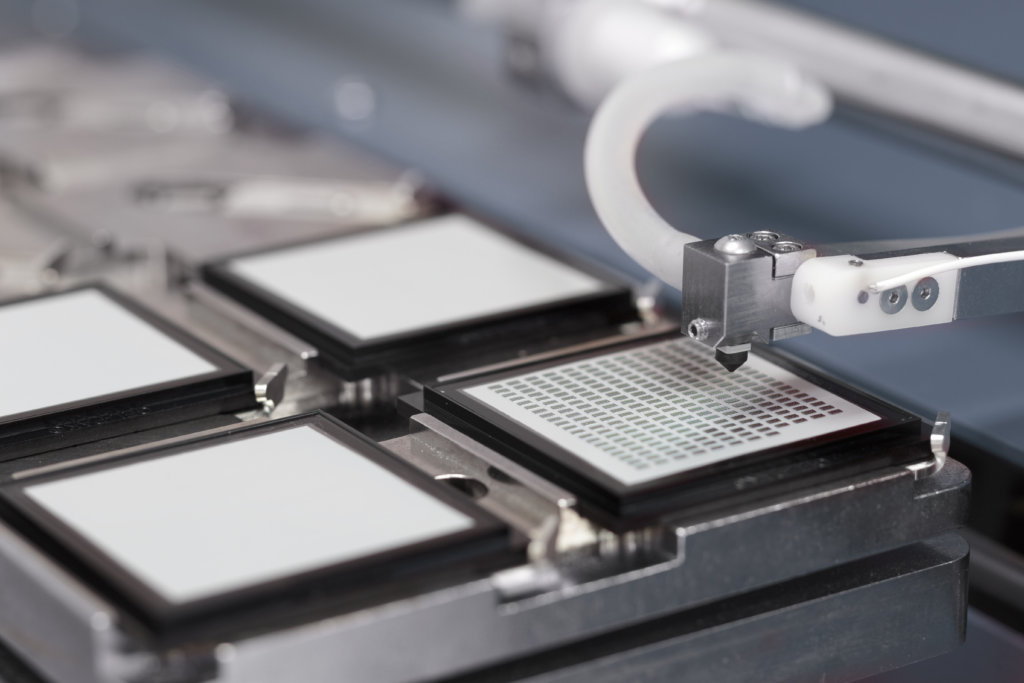

Die Sort / Pick & Place

Following dicing, QP Technologies can select specific die to assemble for assembly, and place the rest in Gel-Pak boxes or waffle packs or leave them on tape for future assembly builds. Utilizing an electronic wafer map from probing or ink-dot recognition, QP Technologies’ automated pick and place sorter can sort dice into the packing media of your choice.

Our automated pick and place tool is designed for high-mix die sorting, including picking multi-project wafers (which are also known as pizza mask, reticle mask, multi-chip, or shuttle-run wafers), or any wafer that does not contain a regular array of die with one pitch in x and one pitch in y.

These wafers, which consist of many die types and sizes on a single wafer, cannot be processed by traditional automatic pick and place systems. This is because many wafer map reading die sorters work by stepping a pre-programmed distance to the next die on the wafer. The flexible wafer mapping approach and rich die binning options of our pick and place system enables rapid accommodation of both current and legacy wafer map formats.

In addition, the system provides superior ability to automatically sort die from tape without damage. The micron resolution die eject mechanism and optimized die eject head design allows for complete control of die plunge up parameters allowing die as thin as 50 microns to be picked without damage. Examples of fragile die include Gallium Arsenide (GaAs) and other III-V materials.

Die Inspection

Our trained inspectors will examine your dice to your specifications. Our inspectors are certified to commercial and MIL STD 883 specifications. We will also work with you to create a custom inspection criteria specific to your design requirements. By performing a 100% die inspection process we will isolate rejects from acceptable dice to ensure higher yields post assembly.

Wafer Washing

Wafer cleaning is a critical function in the semiconductor manufacturing process. It is required during all major stages of device fabrication including device packaging. As device geometries shrink and new materials are introduced, the number of cleaning steps continues to grow at an aggressive rate. Furthermore, each step has different selectivity and defectivity requirements that add to manufacturing complexity. QP Technologies understands these requirements and is expert in cleaning fragile structures without causing damage.