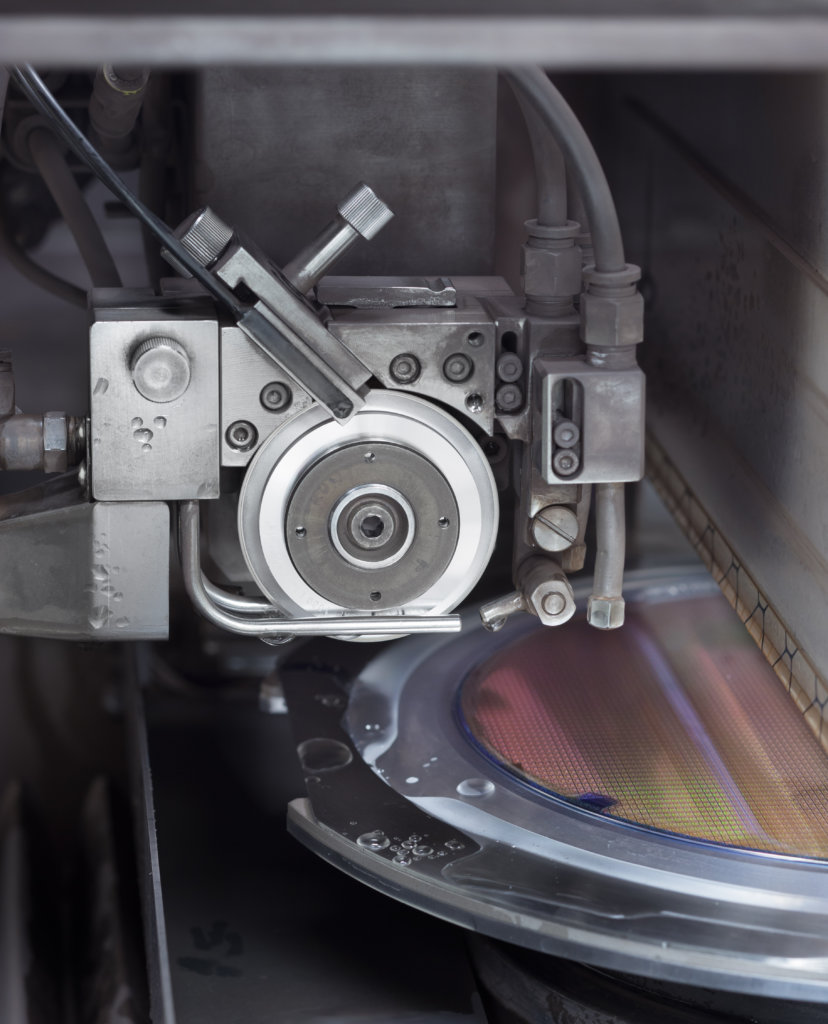

Wafer Backgrinding and Dicing

To meet the requirements of the latest ultra-thin packages, QP Technologies (formerly Quik-Pak) can grind wafers down to as little as 50µm, utilizing state-of-the art automatic surface grinders and Poligrind technology. Disco’s Poligrind wheel technology reduces surface roughness, improves die strength, and reduces wafer warpage.

QP Technologies can backgrind wafers up to 300mm in diameter, as well as partial wafers, bumped wafers and even individual die.

QP Technologies can precisely dice your Silicon Carbide, (SiC) or GaN on Silicon wafers, as large as 300mm, utilizing the state of the art precision dicing saws. Multi-project (MPW), pizza wafers and reticles are easily accommodated—isolating only the dice you need by sacrificing those that you don’t need or remounting wafer pieces and performing intricate dicing maneuvers to save all die in the reticle. QP Technologies can also dice partial wafers and bumped wafers, as well as substrates or panels in other materials such as laminates, ceramic, glass or quartz.

Following wafer dicing, QP Technologies can sort the dice from a wafer map or ink dots into Gel-Paks or waffle packs or chip trays, or leave the sawn wafer on tape for future assembly requirements.

Silicon Carbide

Silicon Carbide (SiC) semiconductors can operate at substantially higher temperatures, voltages, and power levels than silicon-based semiconductors. The combination of these strengths translates into smaller, lighter, and simpler electrical systems. Silicon Carbide is a very difficult material to dice and requires special dicing processes and parameters. QP Technologies utilizes the latest dicing technology from DISCO to efficiently dice this material.